National Standard I Two Component Durable Polyurea Elastomer for Anticorrosive Protective Painting

Package Size 23.50cm * 23.50cm * 37.50cm Package Gross Weight 21.500kg;

Basic Info.

| Model NO. | LY-2711 |

| Gel Time, 24ºC | 10-30s (at 50% Relative Humidity) |

| Density | 0.95-1.05kg/L |

| Dosage | 1.2-1.5kg/M2(Calculated by Thickness 1mm) |

| Solid Content | 100% |

| Transport Package | Steel Drum/IBC Drum/Tank |

| Specification | pure |

| Trademark | G-TECH@ |

| Origin | China |

| Production Capacity | 10000mt/Year |

Packaging & Delivery

Package Size 23.50cm * 23.50cm * 37.50cm Package Gross Weight 21.500kgProduct Description

| Description: | A two-component, solvent-free, high-purity, fast-reaction spray polyurea system; unique formulation design; the cured polyurea elastomer has excellent toughness, weather resistance and water resistance. | |

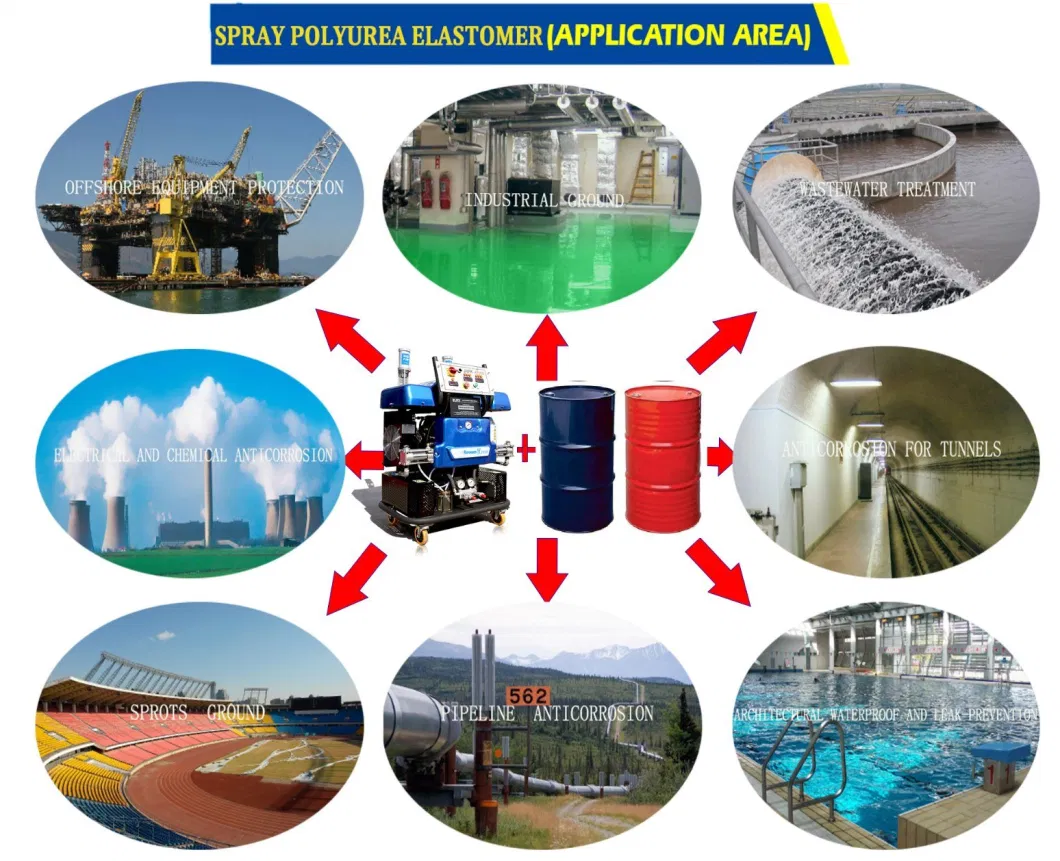

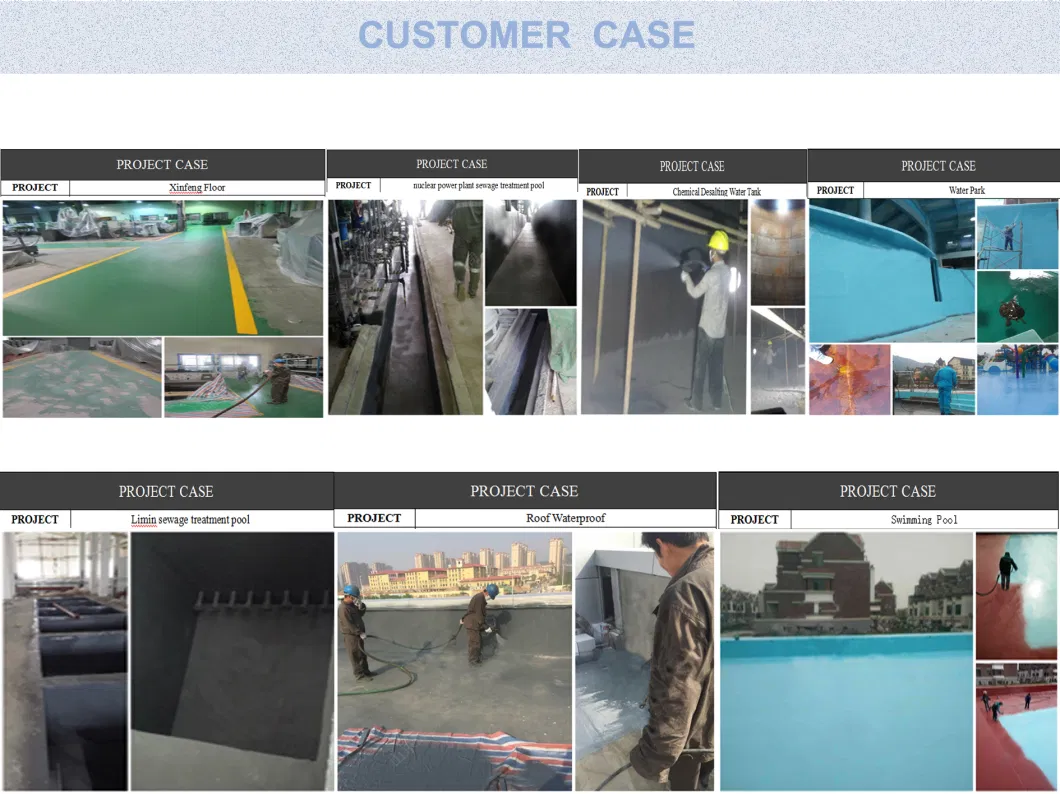

| Application: | It is appiled for anti-corrosion, waterproofing and protection of the various concrete based or metal based surface. | |

Physical Parameters: | Color | Provide standard gray. Customers can also choose colors according to project needs. |

| Solid Content: | 100% | |

| Dosage | 1.2-1.5kg/m2(calculated by thickness 1mm) | |

| Temperature Resistance | -45ºC-180ºC | |

| Density, | 0.95-1.05kg/L | |

| Gel time, 24ºC | 10-30s (at 50% relative humidity) | |

| Track free time, 24ºC | Less than one minute (at 50% relative humidity) | |

| Curing time | 48 hours | |

| Tensile strength,MPa | ≥12 Mpa | |

| Elongation at Break,% | ≥380 | |

| Tear Strength, KN/m | 69 | |

Construction Suggestion | Mixing Ratio | 1:1 by volume |

| Construction Device | Special hydraulic spraying Polyurea machine | |

Construction Method | 1. Clean up the basement. Remove floating dust, oil, rust, and fill holes; | |

| 2. Paint primer. Function: seal moisture, block pores, increase the adhesion strength between polyurea and the base layer; | ||

| 3. Spray polyurea elastomer. The coating is uniform, no spray leakage, and the thickness meets the requirements. Details see the construction plan; | ||

| 4. Apply protective topcoat (if necessary) or perform protective treatment with polyurea coating. Avoid damage after construction. | ||

| Attention | Grease that has been penetrated deeply into the concrete is extremely difficult to remove, which may affect the adhesion of the polyurea coating. It is required to use power tools to treat the surface or use sandblasting and flame methods, and strive to make the surface hard and smooth without pollutants. After treatment, the surface is dense, flat, uniform, dry and without loose layers. The above requirements must be met. | |

| Safety | 1. Please pay attention to the safety items on the packae label. In addition, the safety regulations stipulated by relevant countries or local governments should also be observed. 2. The construction site should have good ventilation facilities. Operators should wear glasses, gloves, masks, etc. to avoid skin contact and inhalation of material mist. The temperature of the material after mixing can reach 120ºC or higher. Beware of burns. Fireworks are strictly prohibited on the construction site. | |

You may also like

Send inquiry

Send now