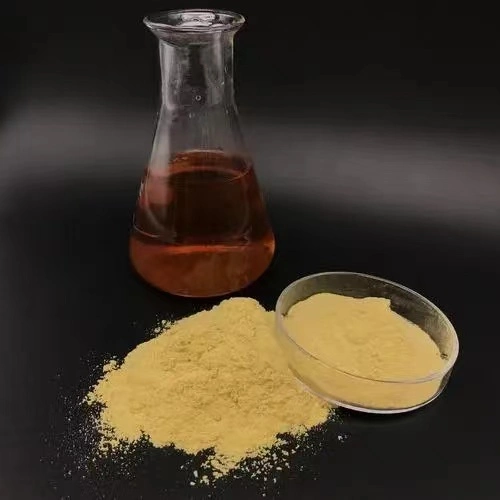

Special Flocculation Water Treatment Chemicals for Leather Factory Sewage Polymeric Ferric Sulfate

This product can be added directly, or the dissolved tank is added first, the concentration is 10 to 20%, stirred, and t;

Basic Info.

| Model NO. | HH-w530756865 |

| Colour | Yellow |

| Transport Package | 25kg/Bag |

| Specification | 40-99 |

| Trademark | henghao |

| Origin | China |

| HS Code | 282732 |

| Production Capacity | 1000000 |

Product Description

This product can be added directly, or the dissolved tank is added first, the concentration is 10 to 20%, stirred, and the pump is added to the reaction tank. This product has a wide range of pH, which is more effective under acidic conditions, which is about 100 ~ 1000ppm (ie 0.1 ~ 1 kg / ton wastewater), which is different depending on the amount of phosphate in wastewater. The specific amount is generally determined by experiments

| Model NO. | Polyferric sulFate 21% | Color | Yellow |

| Appearance | Powder | Type | Sewage Treatment Chemicals |

| Payment | Negotiable | Transport Package | 25kg Bags |

| Specification | 21% | Trademark | Henghao Environmental Protection |

| Origin | China | HS Code | 28273200 |

| Production Capacity | 3000mt Monthly |

This product can be added directly, or the dissolved tank is added first, the concentration is 10 to 20%, stirred, and the pump is added to the reaction tank. This product has a wide range of pH, which is more effective under acidic conditions, which is about 100 ~ 1000ppm (ie 0.1 ~ 1 kg / ton wastewater), which is different depending on the amount of phosphate in wastewater. The specific amount is generally determined by experiments.Hello buyers,

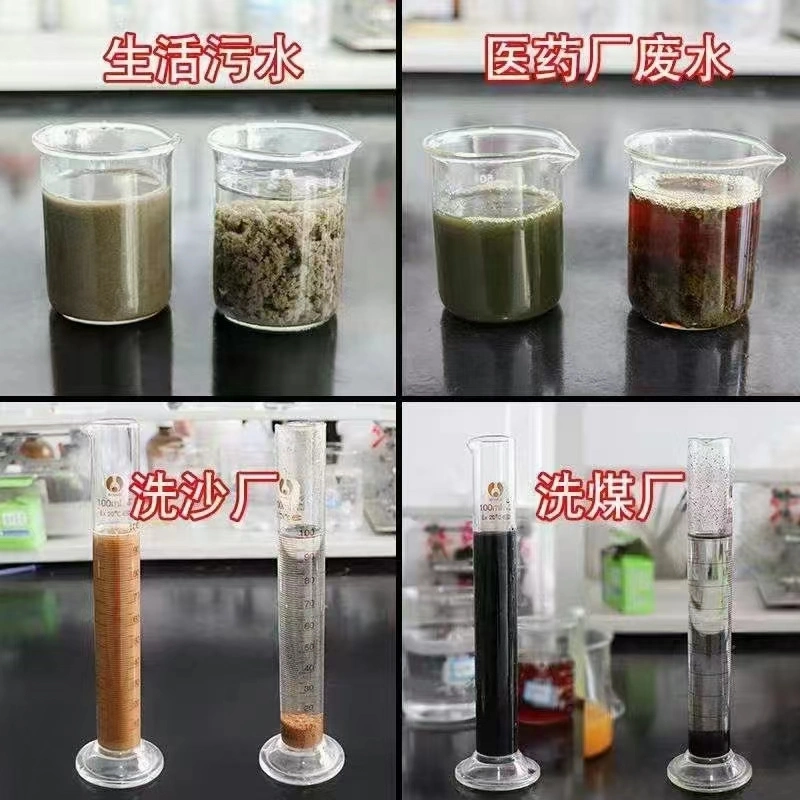

Related products of our water treatment chemicals

Can make relevant customized products according to the water quality indicators;

A certain amount of raw Polymeric ferric sulfate in the treatment of rare earth industrial wastewater: For example, the device keeps the tiny solid particles of the wastewater and the surface of the high-concentration ionic membrane at a certain distance, greatly reducing the chance of harmful substances and the membrane surface to avoid fouling on the membrane surface. Iron improves the over-circulation of water; this process not only separates high concentrations of rare earth extraction process wastewater with enriched ammonium chloride, rare earth industry standard post-wastewater recycling, and passes electrolysis process and solar energy for a successful reactor Recovery, polymerization of ferric sulfate reduces the recovery of raw materials produced by the rare earth industry, and also through the use of fuel cells to recover energy. Added that the cost of processing a large amount of wasted water is 40 yuan, which is 1600 tons/day, including 100g/L of chlorinated Ammonium is calculated, through this process, a generation water can achieve a profit of 110,000 yuan, which is not only the goal of reduction, stabilization and harmlessness for the country's sewage treatment and disposal; strict control of heavy metals in rare earth industrial wastewater and toxic and polymerized ferric sulfate harmful substances; under the premise of safety, environmental protection and economic recovery, use the energy and resources of waste water and polymerized ferric sulfate waste gas to realize waste water and waste gas treatment and comprehensive utilization, energy saving and emission reduction, and realize the development of circular economy. the goal of.

water is taken to add an appropriate amount of this product (such as 500 ppm) to adjust the pH of the wastewater to 7 to 8, and a small amount of polyacrylamide PAM flocculation precipitate is added, and the supernatant is filtered to determine the content of phosphorus. (To handle heavy metals, use the supernatant to carry out the secondary processing.)

Polymeric ferric sulfate uses a combination of dielectric electrophoresis technology and osmotic membrane separation technology to reuse and treat sewage, realize technological innovation and technological progress in wastewater treatment, give full play to the investment and operation efficiency of equipment, suit China's national conditions, and meet the characteristics of Inner Mongolia Autonomous Region. New technologies for wastewater treatment, new technologies for polyferric sulfate and new equipment. If the new technology is widely used, it will improve the treatment and disposal level of industrial wastewater of mining enterprises in this area, and polymerized ferric sulfate will further protect and improve the ecological environment, and promote the sustainable development of our economy, society and environment in this area.

Flocculation technology is widely used in the treatment of oily wastewater due to its strong adaptability, the ability to remove emulsified oil and dissolved oil, and some complex macromolecular organic compounds that are difficult to biochemically degrade. Commonly used flocculants are mainly inorganic flocculants, organic flocculants and composite flocculants.

Among the inorganic macromolecule flocculants, polyaluminum chloride, polyferric sulfate and other lower molecular weight inorganic flocculants have good treatment effect, low price, low dosage, high efficiency and are widely used.

1. The treatment of printing and dyeing wastewater can replace the traditional coagulants of low molecular weight iron salts and aluminum salts. Compared with the traditional coagulants, the amount of coagulants is large, the coagulation efficiency is low, and the residues such as aluminum ions are easy to cause secondary pollution. The dosage is about 150ppm, the dosage is small, the removal rate of COD and chroma is high, and the optimal pH value condition is: 8.0.

2. Electroplating sewage treatment, can be used as coagulant and breaker. The complex is mainly coppecomplex, which is stable in nature, pH=11, and is difficult to directly precipitate with alkali, polyaluminum and other coagulants. It can also be used for reuse of reclaimed water.

3. Papermaking wastewater treatment, instead of polyaluminum chloride, aluminum sulfate, etc., can be used as a coagulant, and can also be used for papermaking sludge dewatering. polymer), only polyaluminum chloride can be used.

Method 1: The raw materials are ferrous sulfate, sulfuric acid and catalyst. Different manufacturing processes can be formed using different catalysts. The process method is to concentrate the sulfuric acid washing solution, adjust the ratio of acid and ferrous iron, add a quantitative amount in a closed pressure vessel, and then introduce oxygen, and under constant temperature and constant stirring, the polymerized ferric sulfate is obtained through the reaction. .

Method 2: The raw materials are FeSO4 and waste H2SO4, the by-products of the titanium dioxide factory. The production process is to determine the content of iron in FeSO4·H2O, dehydrate it by passing hot air, and when it contains 1-2 crystals, pass cold air, and make it into an oxidizing material under the condition of oxidizing agent. At this time, the waste sulfuric acid and solidification After curing, the polyiron product has been formed. The production process is controlled SOi24-: Fe2+(mo1)=1.30:1.45

Method 3: the raw materials are concentrated sulfuric acid and ferrous sulfate; the preparation process is that the concentrated sulfuric acid is directly added to the ferrous sulfate, then an appropriate amount of catalyst MnO2 (or 30% dilute acid is added to the ferrous sulfate and then the catalyst NaNO2) is added, and the After entering the air for oxidation, hydrolysis and polymerization, the polymerized ferric sulfate is prepared.

You may also like

Send inquiry

Send now