PU Construction Materials Polyurethane Spray Super Heavy Anticorrosive Elastomer Polyurea Paint

Package Size 23.50cm * 23.50cm * 37.50cm Package Gross Weight 21.500kg Product Description: A two-component, fast-reacti;

Basic Info.

| Model NO. | LC-3326 |

| Water-Soluble | ≤2.0% |

| Impermeability,0.3 MPa/30min | Impermeable |

| Adhesion to Steel,MPa | ≥10.35 |

| Hardness, Shore D | ≥65 |

| Solid Content , % | ≥99 |

| Transport Package | Steel Drum/IBC Drum/Tank |

| Specification | pure |

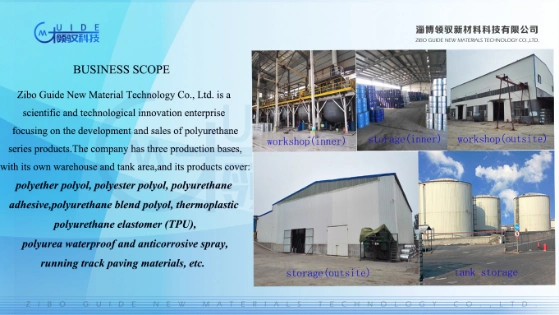

| Trademark | G-TECH@ |

| Origin | China |

| Production Capacity | 10000mt/Year |

Packaging & Delivery

Package Size 23.50cm * 23.50cm * 37.50cm Package Gross Weight 21.500kgProduct Description

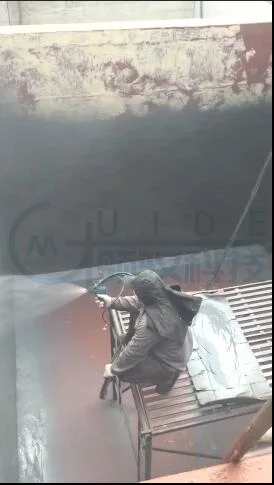

Product Description:A two-component, fast-reacting spray polyurea system. The cured polyurea coating has excellent physical and mechanical properties, outstanding corrosion resistance and weather resistance.

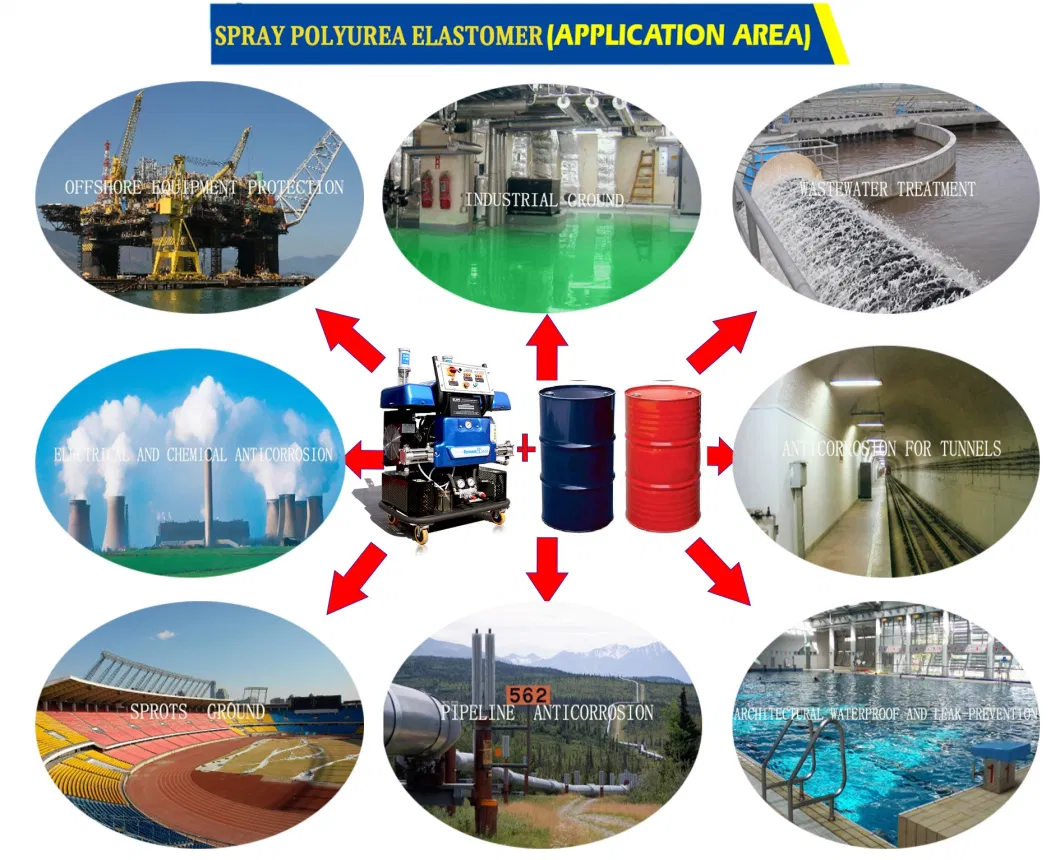

Application Scope:

Anticorrosion and protection of the inner and outer walls of buried metal pipelines (such as, oil transportation pipelines, na tural gas pipelines, tap water pipelines, gas pipelines, etc.).

Integral sealing, joint sealing and welding seam protection of various buried pipelines.

Advantages:

The coating has strong adhesion, and it wraps the pipeline seamlessly and tightly as a whole, forming a permanent anti-corrosion protection layer on the outer wall of the pipeline.

Excellent corrosion resistance and weather resistance make it able to adopt to environmental temperature changes from -40°C to 150°C.

High strength, impact resistance, tear resistance, abrasion resistance, waterproof and impermeability.

Curing speed is very fast and can be sprayed continuously on any curved surface without sagging, and the film thickness is uniform, effectively avoiding missing coating.

The construction efficiency is very high. It only takes 1 hour to coat the outer wall of 200m2 pipeline, and can be buried underground in 30 minutes.

Solvent-free and environmentally-friendly.

Technical Parameters:

| Item | Index | ||

| Drying Time, min | Surface Dry | ≤1 | |

| Internal Dry | ≤60 | ||

| Solid Content , % | ≥99 | ||

| Adhesion to Steel,MPa | ≥10.35 | ||

| Cathodic Stripping (28 days), Stripping Radius | ≤10mm | ||

| Flexibility (bend 180° around axis, 102mm) | No Cracks and Delamination | ||

| Impact resistance(15.9mm half round head),Kg·m | ≥0.46 | ||

| Wear Resistance (CS17 drum, 1000g/1000r, weightlessness, g) | ≤0.1 | ||

| Hardness, Shore D | ≥65 | ||

| Electric Detection | No Missing Point | ||

| Impermeability,0.3 MPa/30min | Impermeable | ||

| Water-soluble | ≤2.0% | ||

| Resistance Against Acid and Alkali(10%H2SO4,10%HCl,30%NaOH,10%KOH, 25ºC,60 days) | Size Change≤5% | No Blistering, No Falling Off, No Rust | |

| Salt Tolerance(10%NaCl,25ºC,60 days) | Size Change≤5% | No Blistering, No Falling Off, No Rust | |

| Oil Resistance (kerosene, diesel, gasoline, 25ºC, 60 days) | Size Change≤5% | No Blistering, No Falling Off, No Rust | |

Packaging and Storage:

Product packaging: component A 55kg/barrel, component B 50kg/barrel.

The product should be strictly sealed and stored in a dry, ventilated and cool indoor warehouse.

The storage period is 6 months. After the expiration date, the product can still be used after passing the test.

You may also like

Send inquiry

Send now